If you’ve ever shopped for commercial playground equipment, you may have been surprised by the high price tags. A single playground structure can range from $10,000 to over $200,000, depending on its size, materials, and features. So, why is playground equipment so expensive?

Here’s a breakdown of the key factors driving the cost of commercial playground structures.

1. High-Quality, Durable Materials

Commercial playgrounds are built to withstand heavy use and harsh weather conditions for decades. Unlike residential playsets made from cheaper wood or plastic, commercial-grade equipment uses:

• Powder-coated steel – Rust-resistant and designed for long-term durability.

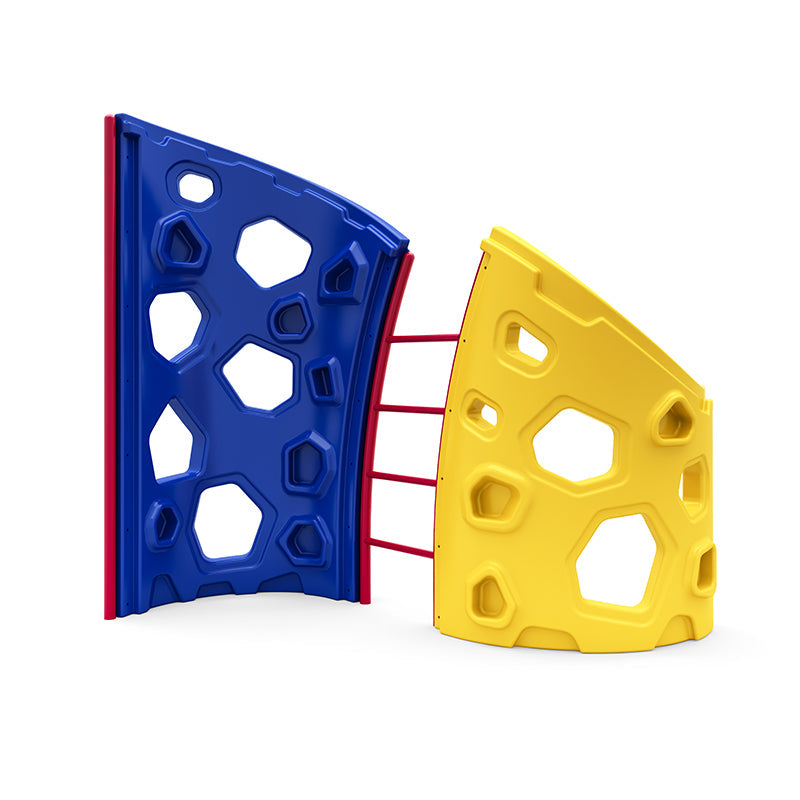

• Rotomolded plastic – UV-resistant to prevent fading and cracking.

• High-density polyethylene (HDPE) – Used for slides and panels, providing a smooth and safe surface.

• Rubber and synthetic surfacing – Safety-tested for impact absorption.

These materials are significantly more expensive than lower-quality alternatives, but they ensure safety, longevity, and compliance with commercial standards.

2. Strict Safety & Compliance Standards

Commercial playgrounds must meet rigorous safety regulations set by:

• Consumer Product Safety Commission (CPSC) – Sets national safety guidelines.

• American Society for Testing and Materials (ASTM) – Establishes industry standards for playground safety.

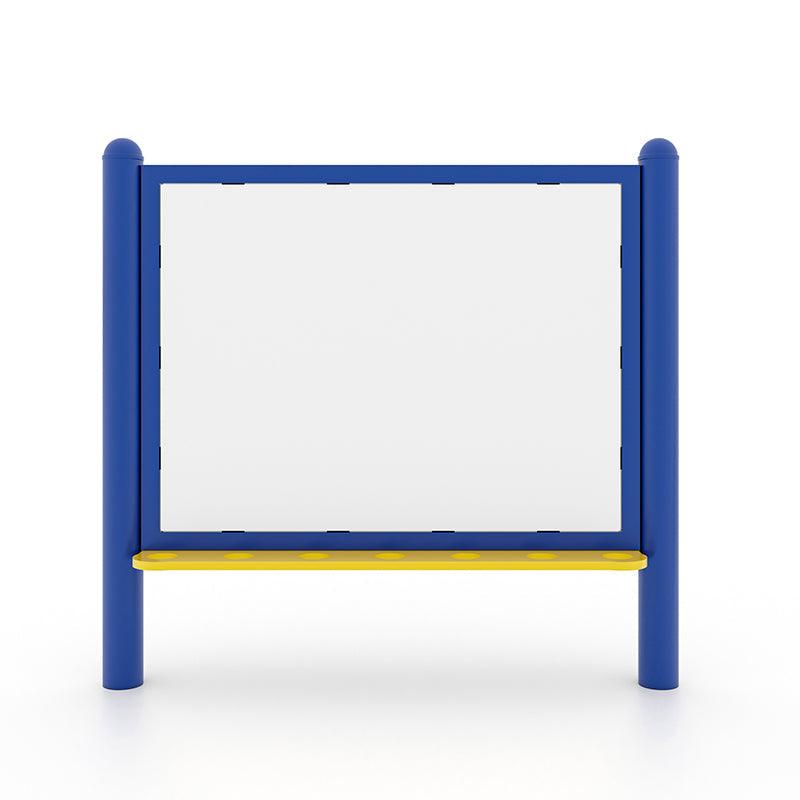

• Americans with Disabilities Act (ADA) – Requires playgrounds to be accessible to all children, including those with disabilities.

These regulations add to the cost because manufacturers must:

✔ Perform extensive safety testing on materials and equipment.

✔ Design ADA-compliant features, such as ramps, ground-level play panels, and wheelchair-accessible swings.

✔ Ensure that no sharp edges, pinch points, or entrapment hazards exist.

Manufacturing CPSC and ASTM-certified playground equipment requires advanced engineering and quality control, which increases production costs.

3. Engineering & Custom Design Costs

Commercial playgrounds are not mass-produced like cheap backyard sets. Each project involves:

• Custom design & engineering – Ensuring structural integrity, accessibility, and site-specific compatibility.

• 3D modeling & testing – Simulating real-world stress to confirm safety.

• Freight & logistics planning – Shipping large, heavy equipment requires specialized transport.

Many playgrounds are customized to fit specific spaces, themes, and budgets, which increases design and manufacturing costs.

4. Installation & Site Preparation

The actual installation process adds significantly to the overall cost. A professional playground installation involves:

• Excavation & grading – Ensuring a level and stable foundation.

• Safety surfacing installation – Adding rubber mulch, engineered wood fiber, or poured-in-place rubber to prevent injuries.

• Anchoring & assembly – Properly securing play structures, swings, and slides to meet safety standards.

On average, installation costs range from 25-45% of the total equipment price. More complex playgrounds, large projects, or those requiring extra site work will cost even more.

For professional installation services, check out PlaygroundProvider.com for a quote.

5. Freight & Shipping Expenses

Playground equipment is large, heavy, and shipped in multiple pieces, often requiring:

• Specialized freight carriers to handle oversized loads.

• Multiple shipments for large playgrounds.

• Crating and protective packaging to prevent damage during transit.

Depending on the distance from the manufacturer, freight costs alone can be thousands of dollars.

6. Playground Surfacing Costs

Safety surfacing is a major cost factor in any playground project. The type of surface you choose will significantly impact the total price.

Here are some common options:

• Engineered wood fiber (EWF) – $3–$5 per square foot (most budget-friendly).

• Rubber mulch – $7–$10 per square foot (mid-range cost).

• Poured-in-place rubber – $15–$30 per square foot (highest safety & ADA compliance).

Playground surfacing is essential for injury prevention and is required by CPSC and ASTM standards, making it a necessary but costly part of any playground installation.

7. Warranties & Longevity

Unlike cheaper residential playsets, commercial playgrounds come with long-term warranties (often 10-20 years or more). This reflects their higher-quality materials, engineering, and durability.

Although the upfront cost is high, commercial playgrounds provide decades of use with minimal maintenance, making them a smart long-term investment.

Final Thoughts: Is Commercial Playground Equipment Worth It?

Yes! While commercial playgrounds are expensive, they offer:

✅ Safety & compliance – Meets strict industry regulations.

✅ Durability – Built with high-grade materials for decades of use.

✅ Customization – Designed to fit specific needs, budgets, and themes.

✅ Community impact – Creates a safe, engaging space for children.

For the best commercial playground equipment, custom quotes, and expert guidance, visit PlaygroundProvider.com.

Looking for funding? Check out these playground grant resources:

• Grants.gov – Federal grants for playground projects.

• NRPA Grants – National Recreation & Park Association funding.

• KaBOOM! – Nonprofit funding for underserved communities.

By investing in high-quality playground equipment, you ensure a safe, fun, and long-lasting play space for children in schools, parks, and public spaces.

Next Steps: Get a Free Quote Today

Ready to start your playground project? Visit PlaygroundProvider.com to explore top-rated commercial playground equipment and get a custom quote today!